Identify the clients requests and facility standards planned by the client through Q&A session prior.

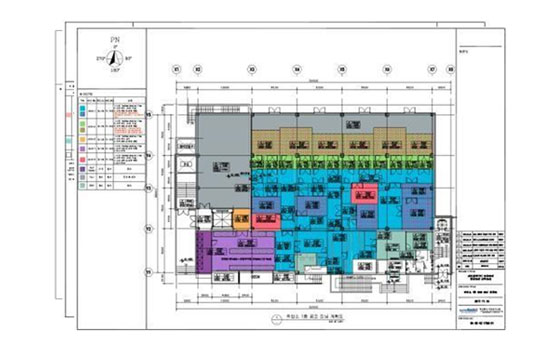

Draw the layout by reflecting the CCS (Contamination Control Strategy), RA (Risk Assessment) and the GMP & GxP requests

within the configuration finalized through the 3D bird’s-eye view.

Draw the GMP floor plan (cleanliness, zoning, pressure differentials, interlocks, personnel flow, material flow etc.) after finalizing the layout.

Floor plan will be drawn in CAD file and finalized after discussing and revising with our clients.

Conceptual design such as the Clean Utility P&ID and BMS, EMS etc. necessary for the Detail Design other than the already drawn GMP & GxP floor plan.

Prepare Room Data Sheet on necessary utility and collaboration methods between each rooms and prepare a report that summarizes the final

product written in accordance with the concept design procedures.